a

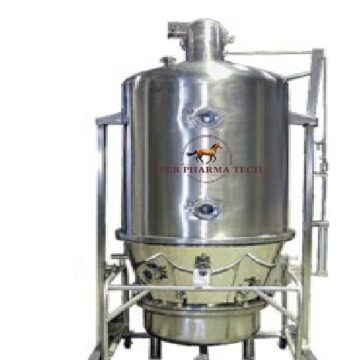

Steel Fluid Bed Dryer

Fluid Bed Dryer Is Designed To Introduce The Hot Air Stream At The Base Of The Product Container, Which Is Filled With The Material. Induced Drought Is Created By Means Of Blower And Fresh Air Is Sucked In To The Unit. The Fresh Air Is Heated By Means Of Electrical Heaters Or Steam Or Thermic Fluid Heaters. This Hot Air Stream Expands The Bed Of Material At Certain Velocity & Creating Turbulance In The Product. The Phenomenon Is Known As Fluidisation And Offer Conditions, Which Are Almost Ideal For Drying. Fluidisation Produces Full Agitation Of Solid Particles And Since Each Particle Gets Surrounded By Hot Air Heat Transfer Is Extremely High And Uniform. The Product Is Dried Fast Without Appreciable Loss Of Heat. Filter Bags Prevent Particles Escaping From The Dryer.

And Capacity Of Fluid Bed Dryers Offered By Us Is Available In The Range Of 30 To 500 Kg, With Steam Heating, Electrical Heating And Thermal Heating Facility. Electrically/Steam And Thermic Fluid Heated In Which General Structure Is Made Out Of Mild Steel And Painted In Standard Model. Made Out Of S.S.304 Quality Material And Polished To The Matt Finished In Gmp Model. The Contact Parts Such As Product Container And Retarding Chamber Are Made Out Of S.S.304/5.S.316 Quality Material, Provided With Non-Flammable Blower Motor, (Flame-Proof Motor Provided On Demand) Suitable To Dry Wet Material.

Stainless Steel Silver Fluid Bed Dryer

Fluid Bed Dryer Is Designed To Introduce The Hot Air Stream At The Base Of The Product Container, Which Is Filled With The Material. Induced Drought Is Created By Means Of Blower And Fresh Air Is Sucked In To The Unit. The Fresh Air Is Heated By Means Of Electrical Heaters Or Steam Or Thermic Fluid Heaters. This Hot Air Stream Expands The Bed Of Material At Certain Velocity & Creating Turbulance In The Product. The Phenomenon Is Known As Fluidisation And Offer Conditions, Which Are Almost Ideal For Drying. Fluidisation Produces Full Agitation Of Solid Particles And Since Each Particle Gets Surrounded By Hot Air Heat Transfer Is Extremely High And Uniform. The Product Is Dried Fast Without Appreciable Loss Of Heat. Filter Bags Prevent Particles Escaping From The Dryer.

And Capacity Of Fluid Bed Dryers Offered By Us Is Available In The Range Of 30 To 500 Kg, With Steam Heating, Electrical Heating And Thermal Heating Facility. Electrically/Steam And Thermic Fluid Heated In Which General Structure Is Made Out Of Mild Steel And Painted In Standard Model. Made Out Of S.S.304 Quality Material And Polished To The Matt Finished In Gmp Model. The Contact Parts Such As Product Container And Retarding Chamber Are Made Out Of S.S.304/5.S.316 Quality Material, Provided With Non-Flammable Blower Motor, (Flame-Proof Motor Provided On Demand) Suitable To Dry Wet Material.

Semi-Automatic Fluid Bed Dryer Processor

Fluid Bed Dryer Is Designed To Introduce The Hot Air Stream At The Base Of The Product Container, Which Is Filled With The Material. Induced Drought Is Created By Means Of Blower And Fresh Air Is Sucked In To The Unit. The Fresh Air Is Heated By Means Of Electrical Heaters Or Steam Or Thermic Fluid Heaters. This Hot Air Stream Expands The Bed Of Material At Certain Velocity & Creating Turbulance In The Product. The Phenomenon Is Known As Fluidisation And Offer Conditions, Which Are Almost Ideal For Drying. Fluidisation Produces Full Agitation Of Solid Particles And Since Each Particle Gets Surrounded By Hot Air Heat Transfer Is Extremely High And Uniform. The Product Is Dried Fast Without Appreciable Loss Of Heat. Filter Bags Prevent Particles Escaping From The Dryer.

And Capacity Of Fluid Bed Dryers Offered By Us Is Available In The Range Of 30 To 500 Kg, With Steam Heating, Electrical Heating And Thermal Heating Facility. Electrically/Steam And Thermic Fluid Heated In Which General Structure Is Made Out Of Mild Steel And Painted In Standard Model. Made Out Of S.S.304 Quality Material And Polished To The Matt Finished In Gmp Model. The Contact Parts Such As Product Container And Retarding Chamber Are Made Out Of S.S.304/5.S.316 Quality Material, Provided With Non-Flammable Blower Motor, (Flame-Proof Motor Provided On Demand) Suitable To Dry Wet Material.

Manual Fluid Bed Dryers

Fluid Bed Dryer Is Designed To Introduce The Hot Air Stream At The Base Of The Product Container, Which Is Filled With The Material. Induced Drought Is Created By Means Of Blower And Fresh Air Is Sucked In To The Unit. The Fresh Air Is Heated By Means Of Electrical Heaters Or Steam Or Thermic Fluid Heaters. This Hot Air Stream Expands The Bed Of Material At Certain Velocity & Creating Turbulance In The Product. The Phenomenon Is Known As Fluidisation And Offer Conditions, Which Are Almost Ideal For Drying. Fluidisation Produces Full Agitation Of Solid Particles And Since Each Particle Gets Surrounded By Hot Air Heat Transfer Is Extremely High And Uniform. The Product Is Dried Fast Without Appreciable Loss Of Heat. Filter Bags Prevent Particles Escaping From The Dryer.

And Capacity Of Fluid Bed Dryers Offered By Us Is Available In The Range Of 30 To 500 Kg, With Steam Heating, Electrical Heating And Thermal Heating Facility. Electrically/Steam And Thermic Fluid Heated In Which General Structure Is Made Out Of Mild Steel And Painted In Standard Model. Made Out Of S.S.304 Quality Material And Polished To The Matt Finished In Gmp Model. The Contact Parts Such As Product Container And Retarding Chamber Are Made Out Of S.S.304/5.S.316 Quality Material, Provided With Non-Flammable Blower Motor, (Flame-Proof Motor Provided On Demand) Suitable To Dry Wet Material.

Industrial Fluid Bed Dryer

Fluid Bed Dryer Is Designed To Introduce The Hot Air Stream At The Base Of The Product Container, Which Is Filled With The Material. Induced Drought Is Created By Means Of Blower And Fresh Air Is Sucked In To The Unit. The Fresh Air Is Heated By Means Of Electrical Heaters Or Steam Or Thermic Fluid Heaters. This Hot Air Stream Expands The Bed Of Material At Certain Velocity & Creating Turbulance In The Product. The Phenomenon Is Known As Fluidisation And Offer Conditions, Which Are Almost Ideal For Drying. Fluidisation Produces Full Agitation Of Solid Particles And Since Each Particle Gets Surrounded By Hot Air Heat Transfer Is Extremely High And Uniform. The Product Is Dried Fast Without Appreciable Loss Of Heat. Filter Bags Prevent Particles Escaping From The Dryer.

And Capacity Of Fluid Bed Dryers Offered By Us Is Available In The Range Of 30 To 500 Kg, With Steam Heating, Electrical Heating And Thermal Heating Facility. Electrically/Steam And Thermic Fluid Heated In Which General Structure Is Made Out Of Mild Steel And Painted In Standard Model. Made Out Of S.S.304 Quality Material And Polished To The Matt Finished In Gmp Model. The Contact Parts Such As Product Container And Retarding Chamber Are Made Out Of S.S.304/5.S.316 Quality Material, Provided With Non-Flammable Blower Motor, (Flame-Proof Motor Provided On Demand) Suitable To Dry Wet Material.

GMP Fluid Bed Dryer

Fluid Bed Dryer Is Designed To Introduce The Hot Air Stream At The Base Of The Product Container, Which Is Filled With The Material. Induced Drought Is Created By Means Of Blower And Fresh Air Is Sucked In To The Unit. The Fresh Air Is Heated By Means Of Electrical Heaters Or Steam Or Thermic Fluid Heaters. This Hot Air Stream Expands The Bed Of Material At Certain Velocity & Creating Turbulance In The Product. The Phenomenon Is Known As Fluidisation And Offer Conditions, Which Are Almost Ideal For Drying. Fluidisation Produces Full Agitation Of Solid Particles And Since Each Particle Gets Surrounded By Hot Air Heat Transfer Is Extremely High And Uniform. The Product Is Dried Fast Without Appreciable Loss Of Heat. Filter Bags Prevent Particles Escaping From The Dryer.

And Capacity Of Fluid Bed Dryers Offered By Us Is Available In The Range Of 30 To 500 Kg, With Steam Heating, Electrical Heating And Thermal Heating Facility. Electrically/Steam And Thermic Fluid Heated In Which General Structure Is Made Out Of Mild Steel And Painted In Standard Model. Made Out Of S.S.304 Quality Material And Polished To The Matt Finished In Gmp Model. The Contact Parts Such As Product Container And Retarding Chamber Are Made Out Of S.S.304/5.S.316 Quality Material, Provided With Non-Flammable Blower Motor, (Flame-Proof Motor Provided On Demand) Suitable To Dry Wet Material.

Fluidized Bed Dryer Pharma Machinery

Fluid Bed Dryer Is Designed To Introduce The Hot Air Stream At The Base Of The Product Container, Which Is Filled With The Material. Induced Drought Is Created By Means Of Blower And Fresh Air Is Sucked In To The Unit. The Fresh Air Is Heated By Means Of Electrical Heaters Or Steam Or Thermic Fluid Heaters. This Hot Air Stream Expands The Bed Of Material At Certain Velocity & Creating Turbulance In The Product. The Phenomenon Is Known As Fluidisation And Offer Conditions, Which Are Almost Ideal For Drying. Fluidisation Produces Full Agitation Of Solid Particles And Since Each Particle Gets Surrounded By Hot Air Heat Transfer Is Extremely High And Uniform. The Product Is Dried Fast Without Appreciable Loss Of Heat. Filter Bags Prevent Particles Escaping From The Dryer.

And Capacity Of Fluid Bed Dryers Offered By Us Is Available In The Range Of 30 To 500 Kg, With Steam Heating, Electrical Heating And Thermal Heating Facility. Electrically/Steam And Thermic Fluid Heated In Which General Structure Is Made Out Of Mild Steel And Painted In Standard Model. Made Out Of S.S.304 Quality Material And Polished To The Matt Finished In Gmp Model. The Contact Parts Such As Product Container And Retarding Chamber Are Made Out Of S.S.304/5.S.316 Quality Material, Provided With Non-Flammable Blower Motor, (Flame-Proof Motor Provided On Demand) Suitable To Dry Wet Material.

Fluid Bed Machine

Fluid Bed Dryer Is Designed To Introduce The Hot Air Stream At The Base Of The Product Container, Which Is Filled With The Material. Induced Drought Is Created By Means Of Blower And Fresh Air Is Sucked In To The Unit. The Fresh Air Is Heated By Means Of Electrical Heaters Or Steam Or Thermic Fluid Heaters. This Hot Air Stream Expands The Bed Of Material At Certain Velocity & Creating Turbulance In The Product. The Phenomenon Is Known As Fluidisation And Offer Conditions, Which Are Almost Ideal For Drying. Fluidisation Produces Full Agitation Of Solid Particles And Since Each Particle Gets Surrounded By Hot Air Heat Transfer Is Extremely High And Uniform. The Product Is Dried Fast Without Appreciable Loss Of Heat. Filter Bags Prevent Particles Escaping From The Dryer.

And Capacity Of Fluid Bed Dryers Offered By Us Is Available In The Range Of 30 To 500 Kg, With Steam Heating, Electrical Heating And Thermal Heating Facility. Electrically/Steam And Thermic Fluid Heated In Which General Structure Is Made Out Of Mild Steel And Painted In Standard Model. Made Out Of S.S.304 Quality Material And Polished To The Matt Finished In Gmp Model. The Contact Parts Such As Product Container And Retarding Chamber Are Made Out Of S.S.304/5.S.316 Quality Material, Provided With Non-Flammable Blower Motor, (Flame-Proof Motor Provided On Demand) Suitable To Dry Wet Material.

Fluid Bed Dryers

Fluid Bed Dryer Is Designed To Introduce The Hot Air Stream At The Base Of The Product Container, Which Is Filled With The Material. Induced Drought Is Created By Means Of Blower And Fresh Air Is Sucked In To The Unit. The Fresh Air Is Heated By Means Of Electrical Heaters Or Steam Or Thermic Fluid Heaters. This Hot Air Stream Expands The Bed Of Material At Certain Velocity & Creating Turbulance In The Product. The Phenomenon Is Known As Fluidisation And Offer Conditions, Which Are Almost Ideal For Drying. Fluidisation Produces Full Agitation Of Solid Particles And Since Each Particle Gets Surrounded By Hot Air Heat Transfer Is Extremely High And Uniform. The Product Is Dried Fast Without Appreciable Loss Of Heat. Filter Bags Prevent Particles Escaping From The Dryer.

And Capacity Of Fluid Bed Dryers Offered By Us Is Available In The Range Of 30 To 500 Kg, With Steam Heating, Electrical Heating And Thermal Heating Facility. Electrically/Steam And Thermic Fluid Heated In Which General Structure Is Made Out Of Mild Steel And Painted In Standard Model. Made Out Of S.S.304 Quality Material And Polished To The Matt Finished In Gmp Model. The Contact Parts Such As Product Container And Retarding Chamber Are Made Out Of S.S.304/5.S.316 Quality Material, Provided With Non-Flammable Blower Motor, (Flame-Proof Motor Provided On Demand) Suitable To Dry Wet Material.